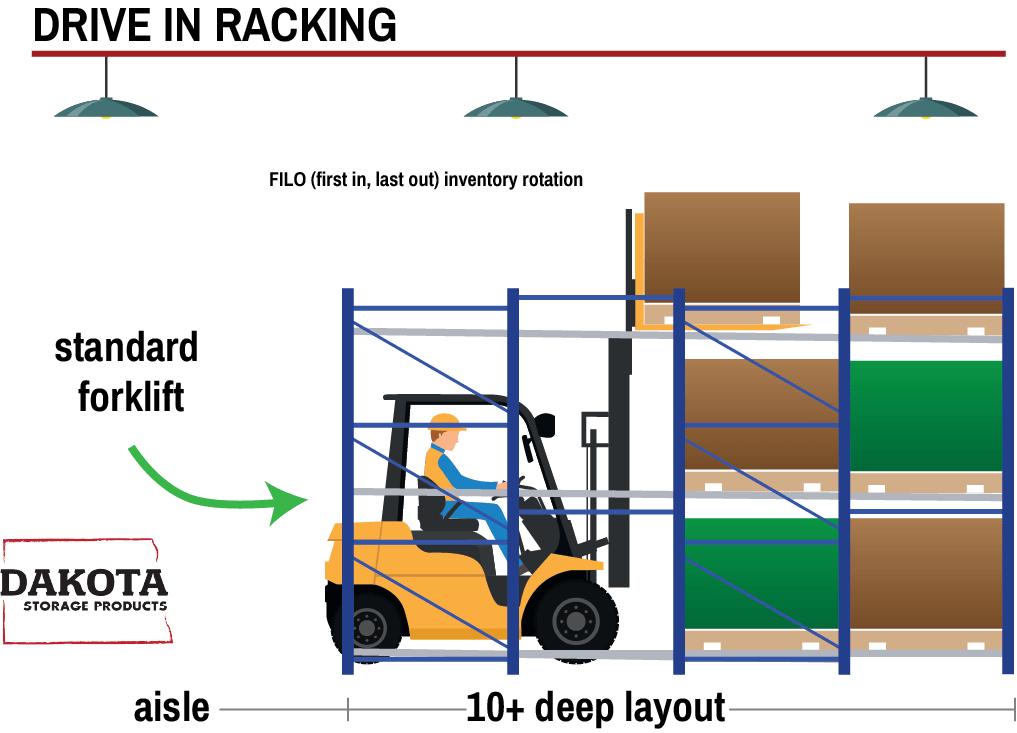

Drive In

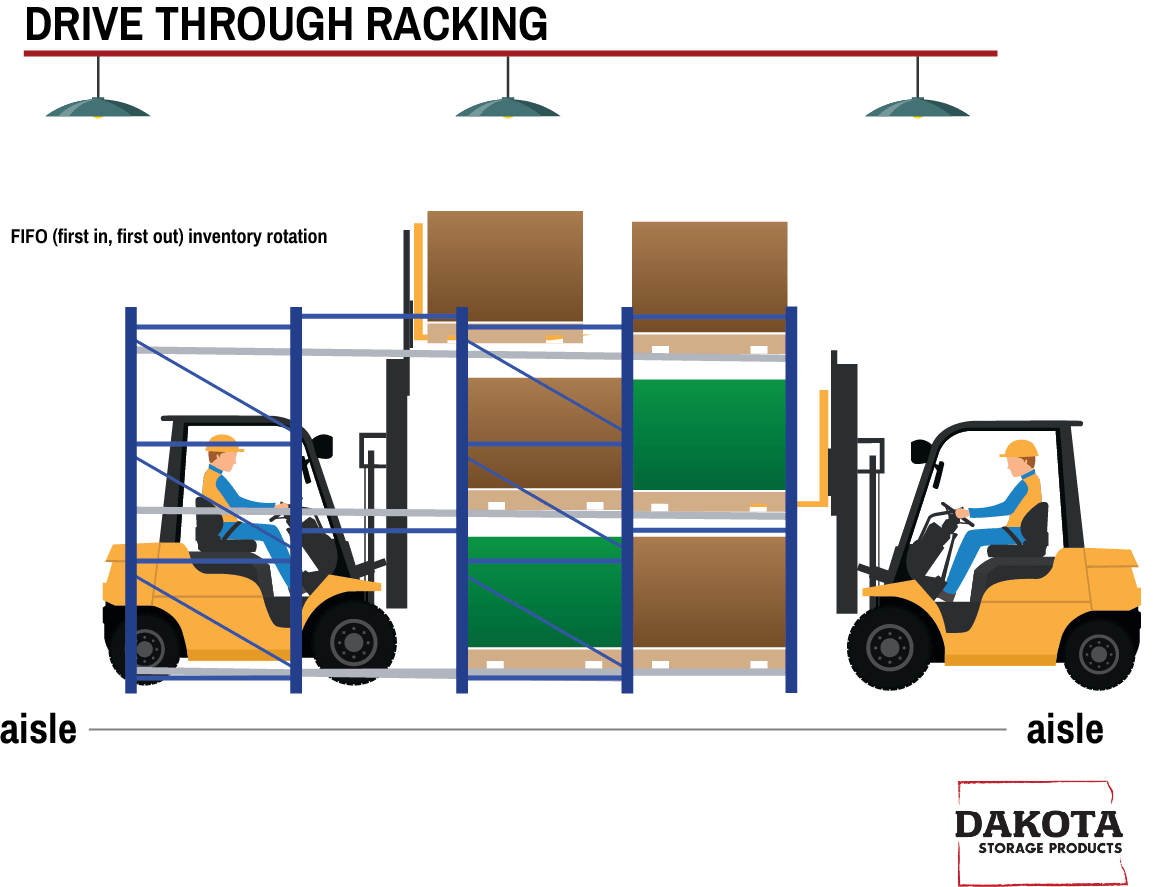

Drive Through

Drive In/Drive Through Racking

Perfect design for high density warehouse requirements

Drive-in/drive-through pallet racking is designed for high-density storage situations. Compared with bulk storage or selective racking, you will save significant warehouse space (with many instances being between 75%-80% space saved).

Drive-in rack is ideal for use cases with high volume but low SKU inventory or the same SKU inventory. Since there is no need for multiple aisles, inventory can be stacked very deep compared to other models of pallet racking. When space is limited, drive-in racking can be the perfect option.

Drive-through racking is best when dealing with products that have expiration dates, as it is rotated using the FIFO (first in, first out) method.

Drive-in pallet racking is designed for high-density storage situations when space is limited and inventory does not need to be accessed from both sides. This is done using the FILO (First In, Last Out) system.

These systems are ideal for use cases with high volume but low SKU inventory or the same SKU inventory. Since there is no need for multiple aisles, inventory can be stacked deep compared to other models of pallet racking.

- Low maintenance and low assembly costs

- Structure compatible with other storage systems

- Over 80% of the available space can be used

- Enables arranged logistics management with full control of inventories as well as traffic and service flow

- Allows for quick reconfiguration as needed

- Ideal for storing low-rotation inventory

- Eliminates service aisles found in a conventional pallet racking system

- Maximized storage footprint

- Easily assembled & modular

Inventory rotation options

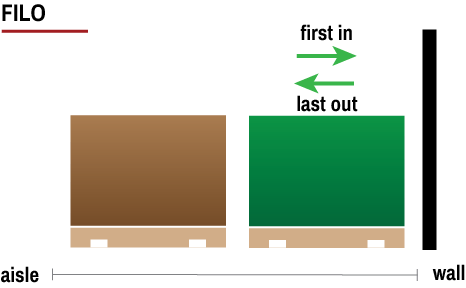

FILO (First in, last out)

Drive in pallet racking is designed with FILO (first in, last out) inventory rotation in mind. The first pallet placed in the system will be the last out of the system. This is why low SKU or same SKU inventory is suggested for these applications, along with a lack of expiration dates.

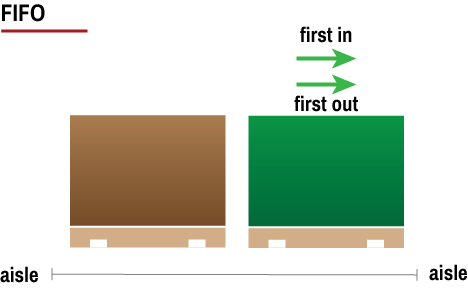

FIFO (First in, first out)

Drive-through racking is set up as FIFO (first in, first out) inventory rotation. Aisles can be set up at either end of the system, with inventory being picked from the back. This allows for the first pallet racks to be used first. This is the preferred setup for inventory with expiration dates.

Forklifts used to set pallets in place

Forklifts drive inside the structure of the racking system, hence the name "drive in" and "drive through" racking. Standard forklifts can be used to set the pallet rack on the rails of the drive in system.

Well-built racking infrastructure to support your warehouse

Drive in racking utilizes frames and vertical uprights to create drive-able inner lanes. Rails are aligned on either side to support pallets as they are set in place. The construction of these units includes stops, tie beams, guide rails, frame protectors, welded base plates, and centering guides. This infrastructure is designed to keep your warehouse staff safe and inventory moving quickly.

405 WEST MAIN AVE - WESTGO SQUARE - WEST FARGO, ND 58078

(701) 281-1209 (800) 252-6401

Hours

Mon - Fri: 8:00 am - 5:00 pm

Sat: By appointment

Pallet Racking & Storage Products dealer serving North Dakota, Minnesota, South Dakota, Montana, and Wyoming.

See all Locations & Areas Served.